Continuous-Flow Synthesis for

Octacalcium Phosphate,

a biodegradable

bone substitute material

Don't you think it's impossible to mass-produce Octacalcium Phosphate (OCP)?

Japan Fine Ceramics has succeeded in the stable production of high-quality OCP at a commercial level.

Why not use OCP to take on the challenge of developing new technologies and make an impact on the medical industry?

Srervices

Japan Fine Ceramics can help you clarify your product needs into requirements for a OCP material and manufacture said material in a timely and accurate manner according to your requirements.

With our team's decades of experience and specialized knowledge, we are able to work together with you to develop your next-generation products, including optimizing material properties and more.

Materials

OctaCalcium Phosphate ---Ca₈H₂(PO₄)₆・5H₂O---

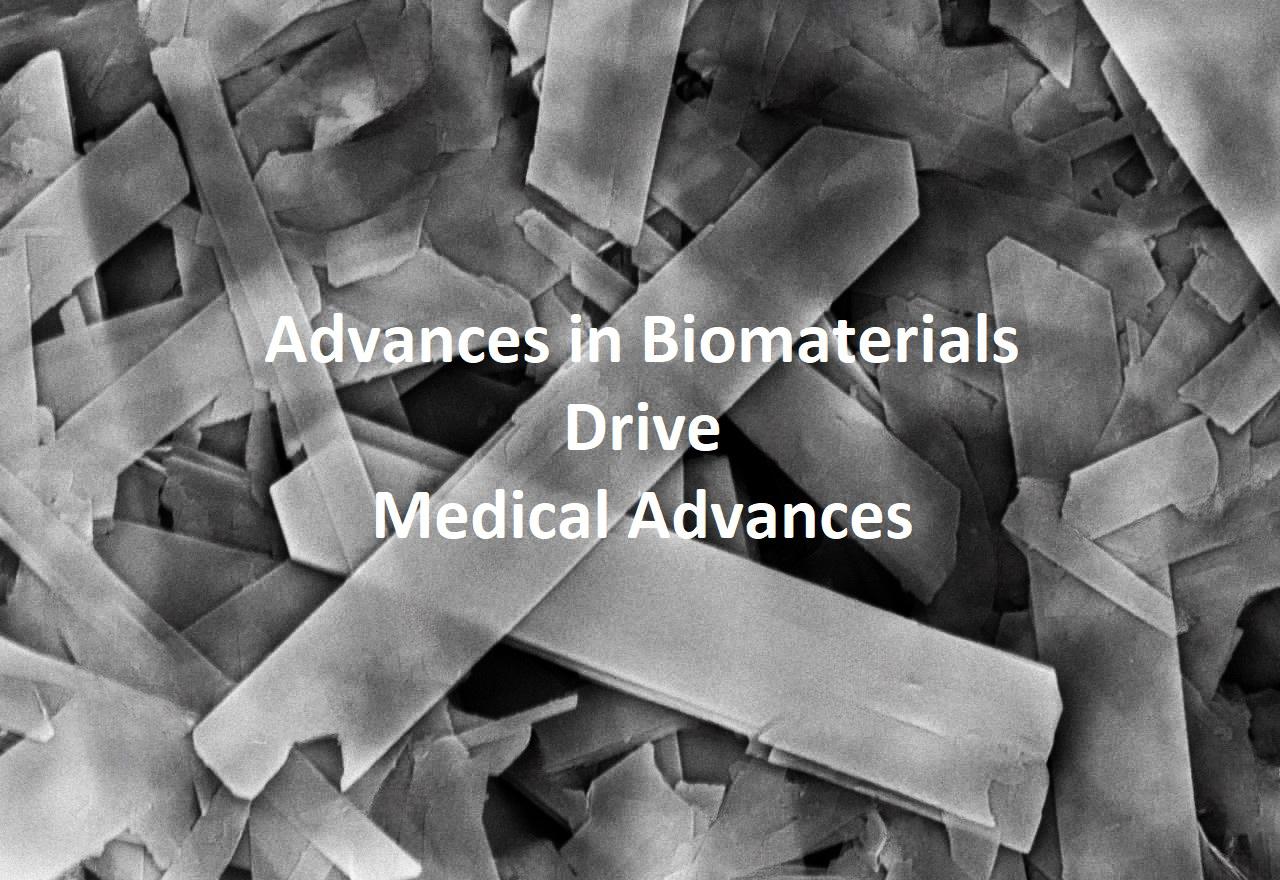

Calcium phosphates, such as hydroxyapatite(Ca10(PO4)6(OH)2, HA) , β-tricalcium phosphate (β-Ca3(PO4)2, β-TCP), and octacalcium phosphate (Ca₈H₂(PO₄)₆・5H₂O, OCP), have attracted attention as a material of artificial substitute. Professor Suzuki et al. reported that OCP exhibits higher osteoconductivity and biodegradability compared to HA and β-TCP through the promotion of osteoblastic differentiation of mesenchymal stem cells and osteoclast formation from macrophages [1].

It is necessary to synthesise OCP in a stable manner in order to apply OCP as artificial bone substitutes. However, it has been recognised that OCP synthesised using standard batch reactors are very difficult to synthesize in large quantities in a stable manner, as the conditions of the reaction field, such as pH and various ion concentrations, are constantly changing [2].

Japan Fine Ceramics has now developed and successfully established at a commercial level the continuous flow synthesis of high-quality OCP to obtain stable and large quantities.

OCP Continuous Flow Synthesis

The OCP continuous-flow synthesis method developed by our company is an unprecedented synthesis method in which solution is continuously fed into the reaction field and discharged at a constant rate. With commercially available crystallisers, it has been difficult to continuously synthesise large quantities of OCP due to several problems. However, our continuous crystalliser has solved the problems and made it possible to obtain high-quality OCP in a stable manner.

The XRD pattern of the product prepared by the newly developed synthesis system shows typical diffraction corresponding to OCP without the appearance of calcium phosphate such as dicalcium phosphate dihydrate (CaHPO4・2H2O, DCPD) and HA, suggesting that the product is a monophase OCP (Fig. 1).

We have achieved a production rate of more than 150 g/day(8hrs) using the continuous flow synthesis, which includes the synthesis to granulation process. In addition, scale-up is relatively easy because it is a continuous flow synthesis system.

Reference

[1] O Suzuki, Y Shiwaku, R Hamai. Octacalcium phosphate bone substitute materials: Comparison between properties of biomaterials and other calcium phosphate materials. Dental Materials Journal, 2019; 39:187-199. Doi: 10.4012/dmj.2020-001

[2] R. O'Sullivan, D. Kelly. Synthesis methodologies options for large-scale manufacturer of octacalcium phosphate. Octacalcium Phosphate Biomaterials Ed. by O. Suzuki, G. Insley. Elsevier, 2019:147-176.