Sustainability

We want our company, our employees, and society to be sustainable.

We would like to introduce the sustainability initiatives that JFC is taking.

01

Technology Innovation

Contributing to the realization of a global low-carbon society

Succeeded in mass production of silicon nitride substrates for power semiconductors.

JFC has succeeded in developing mass production technology for "silicon nitride substrates for power semiconductors" based on technology owned by the National Institute of Advanced Industrial Science and Technology (Chu-bu Center). This technology is being increasingly adopted by users as a high-heat dissipation insulating substrate for mounting power semiconductors, which are essential for the electrification of automobiles.

In October 2024, we received the 2024 Corporate Environmental Achievement Award from the American Ceramic Society, a global academic organization, in recognition of our contribution to the realization of a global low-carbon society. This award is given to companies that have achieved the development and social implementation of new processes and products and have made a certain level of environmental contribution to the world. Encouraged by this award, we will continue to contribute to a sustainable society through the transformation of fine ceramics.

02

Production process

Efforts to maintain high productivity without loss (TPM activities)

In 2006, we started and established Total Productive Management (TPM) activities, which have cultivated the on-site capabilities that JFC is proud of. TPM activities aim to prevent "losses" such as breakdowns, product defects, and wasteful work by properly maintaining and continuing to improve manufacturing plants and equipment. It is characterized by focusing on loss and targeting zero loss. In TPM activities, the difference between the ideal operating state of equipment and processes and the current operating state is considered to be "loss". In order to reduce loss, we have created a culture in which loss is clearly recognized and quantified, and improvement proposals are made and accepted by everyone, from young employees to veterans. Maintaining high productivity without loss also leads to reducing the environmental impact.

03

Creating a corporate culture

A cycle in which employees' dreams lead to organizational growth and social contribution

Based on the idea that "trust creates great power," JFC has fostered a culture that values respect among employees and accepts diverse values. It is this culture that supports the dreams and challenges of research and development and is the driving force behind the creation of new value. Furthermore, the trust in JFC's corporate culture has led to multiple M&A inquiries, and one of the major characteristics of JFC's history is that it has grown while accepting different corporate cultures. With employees who have dreams and take on challenges of their own accord, and who combine diverse knowledge, we will continue to evolve as a sustainable company. We believe that this cycle built on trust will not only contribute to the growth of the company, but also to the development of society.

JFC has various policies to be sustainable.

The company cares about the safety and security of its employees, and

aims for its employees to have dreams and continue to take on new challenges, so that both the company and its employees can grow together.

Through the manufacturing of fine ceramics

Pursuing the happiness of our employees and their families

We contribute to the development of a prosperous future for humanity and the earth.

We act with shared values

-

Challenge

We will continue to listen to our customer's requests and the demands of society, and take on new challenges.

-

Trust

By having all employees care about each other and supporting each other, we can build relationships of trust and increase the strength of both individuals and the company.

-

Passion

We will not compromise on manufacturing, but will demonstrate our on-site capabilities to create competitive products.

-

Cheerful and lively

We will try to be interested in everything, and will take on challenges positively without being discouraged by failure once or twice.

We aim to achieve our management philosophy by living in harmony with the global environment and meeting the expectations of our customers and other stakeholders.

- With "zero complaints" as our common goal, we strive to improve product quality, shorten lead time, reduce costs, comply with customer requirements and laws and regulations, prevent environmental pollution, and improve and enhance the environment.

- We clarify and comply with environmental laws, regulations and other requirements, and strive to reduce the environmental impact from the procurement of raw materials to the shipment of products.

- Through in-house education and awareness-raising activities, we strive to ensure that all employees recognize the importance of quality and environmental conservation.

- We will set quality and environmental targets and strive to achieve them. Furthermore, we will review these targets periodically or as necessary.

- We will establish and operate a quality and environmental management system and promote its continuous improvement.

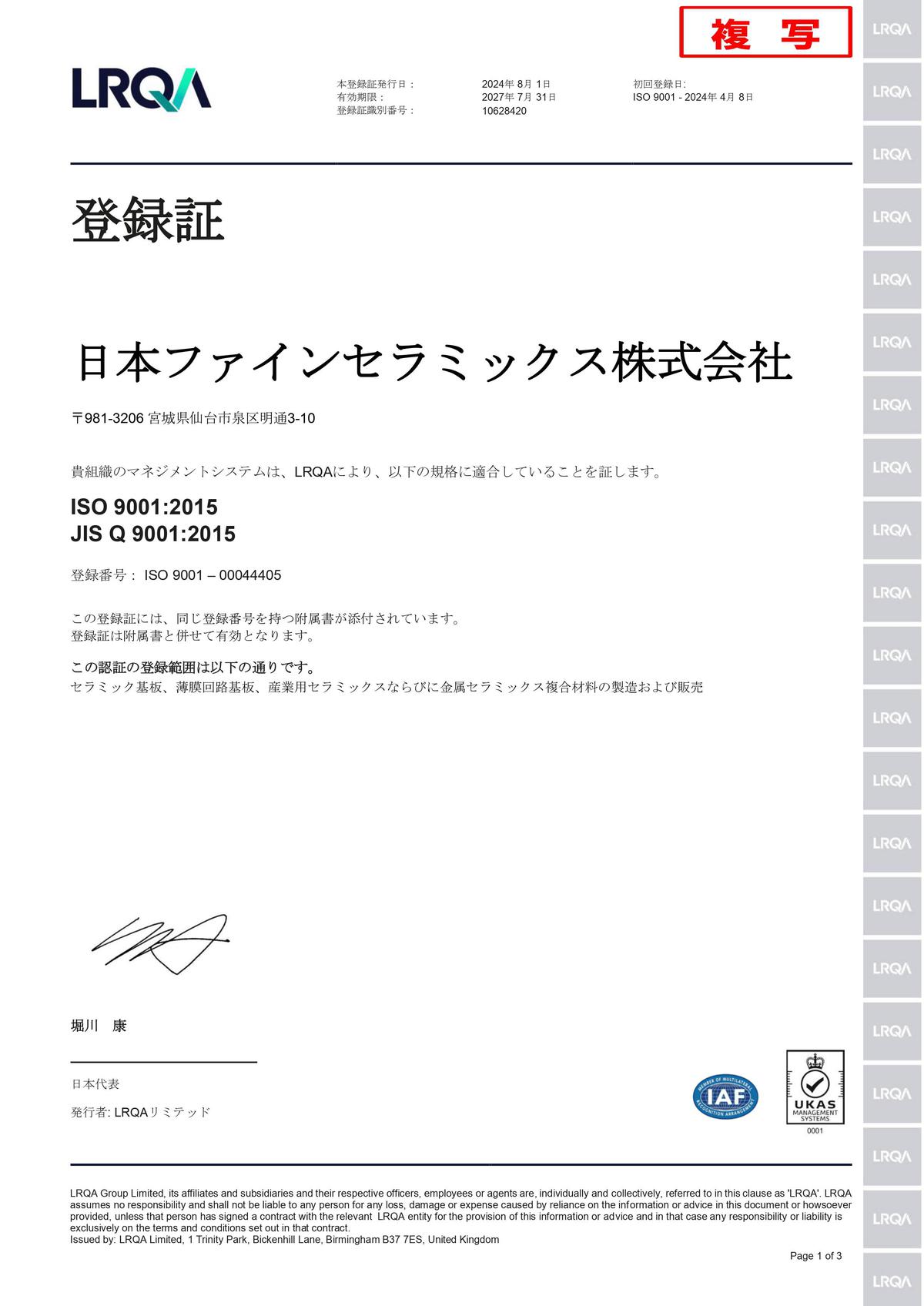

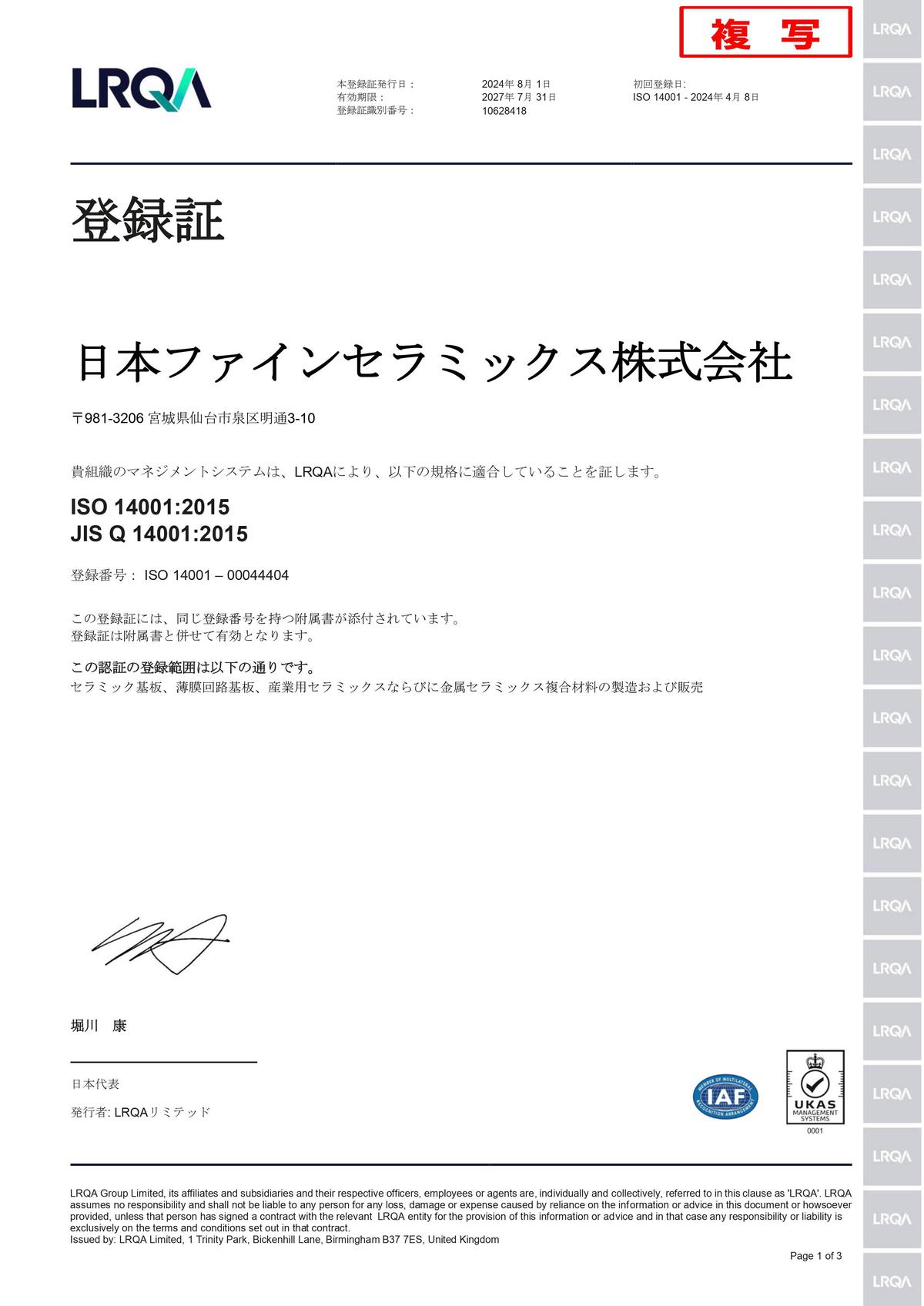

Quality and Environmental Management System

- ISO9001 certified.

- ISO14001 certified.

◾️ Quality Management System Certificate

The scope of registered certification is as follows:

[Product lineup]

Design and manufacturing of ceramic substrates, industrial ceramics and metal ceramic composites

[Applicable business establishments]

- Head office factory

- MMC 1st Factory, MMC 2nd Factory

- Tokyo Sales Office

- Tomiya Office

- Meito 1st Factory, Meito 2nd Factory

- Iwate 1st Factory, Iwate 1st Factory

- Nagoya Sales Office

◾️ Environmental Management System Certificate

The scope of registered certification is as follows:

[Product lineup]

Design and manufacturing of ceramic substrates, industrial ceramics and metal ceramic composites

[Applicable business establishments]

- Head office factory

- MMC 1st Factory, MMC 2nd Factory

- Tokyo Sales Office

- Tomiya Office

- Meito 1st Factory, Meito 2nd Factory

- Iwate 1st Factory, Iwate 1st Factory

- Nagoya Sales Office

In accordance with our quality and environmental policies,

- We develop, design, and manufacture environmentally friendly products by purchasing and using raw materials, parts, and products that have a low environmental impact.

- Comply with laws and regulations regarding chemical substances, including customer agreements and conflict minerals disclosure rules.

- We will not use any prohibited chemical substances or products that contain such substances as stipulated by laws and regulations regarding chemical substances.

- The company will also properly manage the use of controlled chemical substances and strive to replace them with safer substances.

- To this end, we ensure that risk assessments are carried out when purchasing chemical substances.

- By delivering these products to our customers, we contribute to protecting the global environment and building a recycling-oriented society.

Recognizing that protecting information assets, including customer information, is an important management issue, we will protect information assets from all threats.

- Under the supervision of the department manager, information assets will be appropriately protected.

- Clarify how information assets will be handled based on their importance.

- We will clarify and comply with laws, regulations and other requirements regarding the protection of information assets.

- Through education and enlightenment, we will strive to raise awareness among all employees regarding the protection of information assets and ensure thorough implementation of protection measures.

- We will establish and operate a management system for protecting information assets and will promote its continuous improvement.

Through TPM activities, we aim to change the way we think, change ourselves, change the way we work, improve the quality of our work, and become a global manufacturer.

- Not only the production department but also the sales, development, and management departments will participate, making this a company-wide activity.

- From the president on down, each employee will set goals and strive to achieve them.

- We pursue quality improvement in all aspects, including product quality, delivery time, cost, and service.

- We will develop human resources with leadership skills who can live up to the trust of our customers and contribute to the local community.

- We develop human resources with manufacturing skills that surpass those of other companies.

Ensuring the safety and health of employees is our top priority, and we will work to prevent workplace accidents, promote health maintenance and improvement, and create a comfortable workplace.

- We will clarify and comply with laws and regulations, such as the Industrial Safety and Health Act, and other requirements.

- We will continue to improve safety and health education and strive to raise awareness of safety and health.

- Strive to create a safe working environment and achieve zero workplace accidents.

- We will strive to reduce overtime work and promote health maintenance and improvement.

- Eliminate illegal discrimination such as harassment and create a safe and comfortable working environment.

- We will establish and operate a health and safety management system and promote continuous improvement of the system.

We introduce various policies of the JGC Group.

Clicking on the link will take you to the website of JGC Holdings Corporation.